Mold Release Wax agent for Composite FRP Demoulding

$141-9 Others

$13.710-199 Others

$13.5≥200Others

| Payment Type: | L/C,T/T,Western Union |

| Port: | Shanghai Port of China |

$141-9 Others

$13.710-199 Others

$13.5≥200Others

| Payment Type: | L/C,T/T,Western Union |

| Port: | Shanghai Port of China |

Classification: Chemical Auxiliary Agent

CAS No.: mold release wax

Other Names: releasing agent

EINECS No.: 231-545-4

Place Of Origin: China

Type: release wax

Usage: Plastic Auxiliary Agents, FRP and mold release wax

Brand Name: Thousands Chemicals

Model Number: 5-NC

Name: FRP and mold release wax releasing agent

Application: mold demould

Appearance: Clear, colorless

Chemical Type: Solvent Based Polymer

Odor: Solvent

Cure: Room temperature cure

Cured Thermal Stability: ≤400 °C

Application Temperature: 20 to 60 °C

Purity: 100%

Brand: Thousands chemicals

Model: 5-NC

| Selling Units | : | case |

| Package Type | : | 1 gallon/drum |

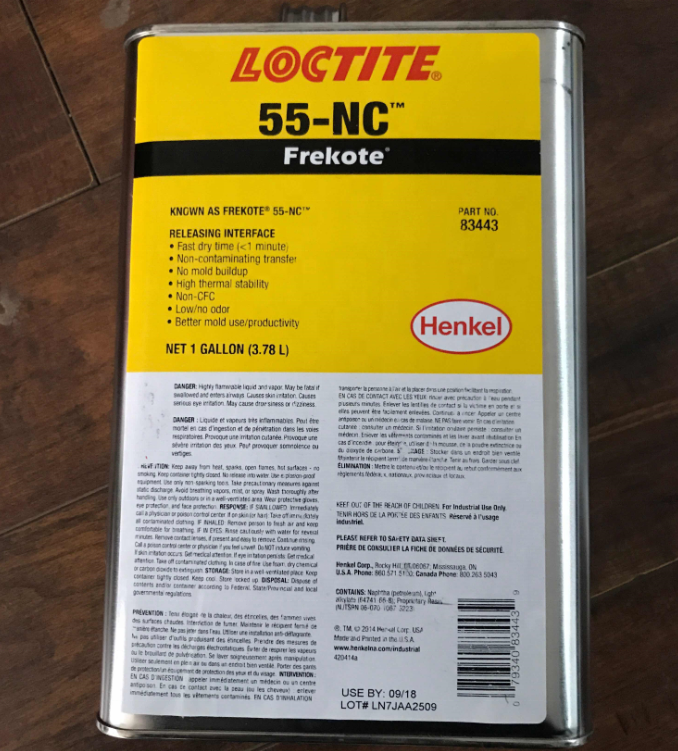

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

LOCTITE® FREKOTE 55-NC™

| Technology | |

| Appearance | Clear, colorlessLMS |

| Chemical Type | Solvent Based Polymer |

| Odor | Solvent |

| Cure | Room temperature cure |

| Cured Thermal Stability | ≤400 °C |

| Application | Release Coatings |

| Application Temperature | 20 to 60 °C |

| Specific Benefit | Fast drying Non-contaminating transfer High thermal stability Non-CFC No mold build-up |

LOCTITE® FREKOTE 55-NC™ is a release agent where a non-transferring release is necessary. This semi-permanent, non-migratory release system chemically bonds to the mold surface to form a micro thin film which is stable at temperatures exceeding most molding processes. LOCTITE® FREKOTE 55-NC™ can be used for the release of epoxies, polyester resins, thermoplastics, adhesives, and rotationally molded plastics.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 °C 0.715 to 0.725LMS

Flash Point - See SDS

This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the Safety Data Sheet (SDS).

Mold Preparation Cleaning:

Mold surfaces must be thoroughly cleaned and dried. All traces of prior release must be removed. This may be accomplished by using Loctite® Frekote® PMC or other suitable cleaner. Loctite® Frekote® 915WB™ or light abrasives can be used for heavy build-up.

Occasionally, green or freshly repaired molds are rushed into service prior to complete cure causing an increased amount of free styrene on the mold surface. Fresh or "production line" repairs, new Fiberglass and Epoxy molds should be cured per manufacturer's instructions, usually a minimum of 2 -3 weeks at 22°C before starting full-scale production.

Fully cured previously unused molds should be sealed before use. This can be accomplished by applying one to two coats of an appropriate Frekote® mold sealer, following the directions for use instructions. Allow full cure of the appropriate Frekote® mold sealer before you apply the first coat of LOCTITE® FREKOTE 55-NC™ as outlined in the directions of use.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.