high quality frp mold gelcoat resin

$3000≥1Others

| Payment Type: | L/C,T/T,Western Union |

| Min. Order: | 1 ton |

| Port: | Shanghai Port |

$3000≥1Others

| Payment Type: | L/C,T/T,Western Union |

| Min. Order: | 1 ton |

| Port: | Shanghai Port |

Model No.: TC-3303

Brand: tc

CAS No.: 9002-86-2

Other Names: frp mold gelcoat resin

MF: Ch2-Chcl-]n

EINECS No.: 208-750-2

Type: Synthetic Resin And Plastics

Brand Name: thousands chemicals

Model Number: TC-3303, TC-3303

Usage: frp mold gelcoat resin

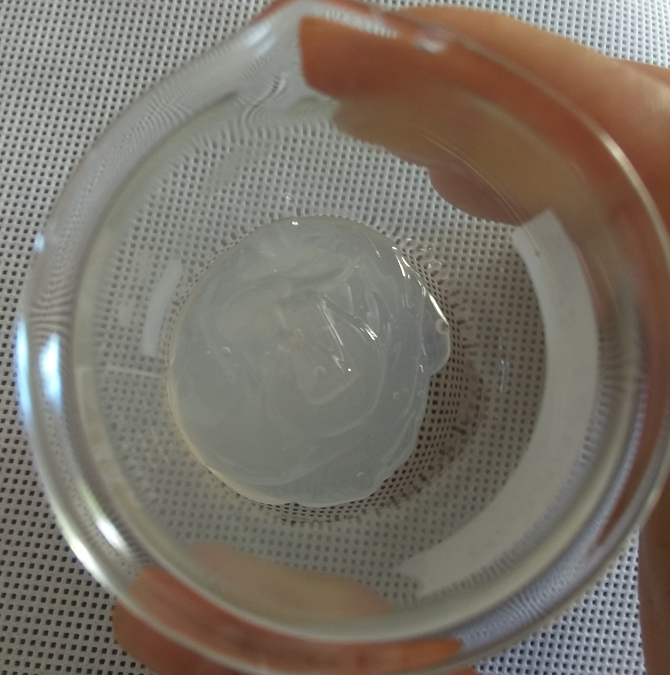

Appearance: A white viscous liquid

Acid Value: 13-20mgKOH/g

Viscosity,25℃: 0.9-1.3Pa.s

Solid Content: 59-72%

Thixotropic Index: 4.0-6.0

Gel Time ,25℃: 8-18 min

Heat Stability,80℃: ≥24h

PACKING: 20kg/drum

Purity: 68-75%

Place Of Origin: Jiangsu, China

| Selling Units | : | ton |

| Package Type | : | metal barrel |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Gelcoat is a resin system that is filled with colorants and thickening agents and applied to a mold surface to form the cosmetic and weathering coating of a composite part. Gel coat is typically the first layer of a part to be applied. Correct application of gelcoat is critical to get the optimum performance from it.

Gelcoats are based on a thermoset resin that requires an initiator and proper temperatures to cure thoroughly. Incomplete cure will result in poor durability of the gelcoat. This is often witnessed as premature fading, dulling of the gelcoat surface, or chalking. There are 3 variables that affect proper cure: temperature, film thickness, and initiator level.

Temperatures should be between 60-80 degrees F. with an optimum range being between 70-75F. We like to use an infrared thermometer to check the temperature of the mold surface and gelcoat. We use the infrared and a wall thermometer to check ambient temperature of the workspace. Keep in mind that molds stored in areas that are not climate controlled may not reach room temperature for quite some time.

Gelcoat should be initiated (catalyzed) to set up to the point that you can touch it with a glove and not have it come up on your finger in 45-60 minutes from application. Generally speaking and depending on the temperature a catalyst ratio of between 1.2% to 3% will give you the proper cure rate.. At 77F 1.8% MEKP will provide a gel time of 10-17 minutes. Keeping good notes will help you build a database of initiator levels for temperatures that you encounter frequently. Gelcoat that is over-initiated can result in excessive shrinking and premature release from the mold.

liquid resin property

| Item | Data | Unit | Testing standard |

| Appearance | A white viscous liquid | — | - |

| Acid value | 13-20 | mgKOH/g | GB/T 2895-2008 |

| viscosity,25℃ | 0.9-1.3 | Pa.s | GB/T 7193-2008 |

| Solid content | 59-72 | % | GB/T 7193-2008 |

| Thixotropic index | 4.0-6.0 | — | — |

| Gel time ,25℃ | 8-18 | min | GB/T 7193-2008 |

| Heat stability,80℃ | ≥24 | h | GB/T 7193-2008 |

Notes:25℃ gel time testing:25℃ water bath, 50g resin filled with 0.9g T-8M(1%Co)and 0.9g M-50(Akzo-Nobel)

casting body property

| Item | Unit | Typical data | Testing method |

| Appearance | Casting body no fault | - | - |

| Barcol hardness | —— | 45 | GB/T 3854-2005 |

| HDT | ℃ | 75 | GB/T 1634-2004 |

| Bending strength | MPa | 100 | GB/T 2567-2008 |

| Tensile strength | MPa | 60 | GB/T 2567-2008 |

| Elongation at break | % | 2.2 | GB/T 2567-2008 |

| Bending modulus | Mpa | 3500 | GB/T 2567-2008 |

| Tensile modulus | Mpa | 3500 | GB/T 2567-2008 |

Notes: resin casting body property standard according to Q/320411 BES002-2014

Our standard gelcoats are designed to cure in films as thin as 12mils (0.012 inches); however, we recommend that you apply them in coats of 18-20 mils to get the best cure, hide, and print block. As the gelcoat cures, it develops heat that helps it complete the cure cycle. If your coating is too thin and the temperature is too low, it will not cure properly. Gelcoat can be applied in coats up to 24mils. For applications under the waterline a thickness of 20-24 mils aids in blister prevention and is better than thinner layers. Thicker layers are more prone to cracking under stress.

Styrene vapors will inhibit and slow the cure of gelcoat. Because styrene is heavier than air it will pool at the bottom of a mold cavity and slow down the cure of the gelcoat located in the bottom or lower parts of a mold. If you have the ability to do so, rotate the mold so that while the gelcoat is curing the styrene vapors can pour out of the mold. If you do not have that ability, make sure to check low spots in the mold as well as high spots for the cure rate of the gelcoat. Slow moving fans can also be used to move the styrene out of the mold cavity.

PACKAGE:20kg pails

STORAGE:maximum of 3 months under 25V in shade

TRANSPORTATION:according to the rule of dangerous good control and GB 190-90

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.