Novolac Epoxy Vinyl Ester Resins

$3≥1000Others

| Payment Type: | L/C,T/T,Western Union |

| Min. Order: | 1000 kilogram |

| Port: | Shanghai Port of China |

$3≥1000Others

| Payment Type: | L/C,T/T,Western Union |

| Min. Order: | 1000 kilogram |

| Port: | Shanghai Port of China |

Model No.: SWANCOR 907

CAS No.: un-available

Other Names: VE resin

MF: un-available

EINECS No.: un-available

Type: Synthetic Resin And Plastics

Brand Name: Swancor

Model Number: 901-200

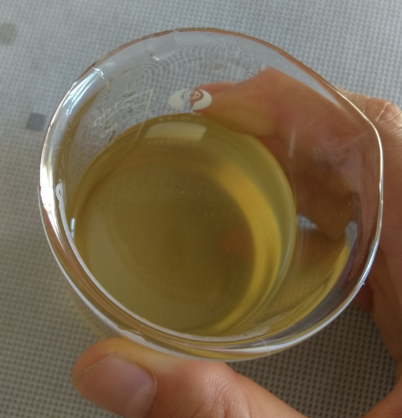

Appearance: Light yellow transparent liquid

Density: 1.06±0.02kg/L

Viscosity: 430±150 cps (LVT#3-60rpm/25℃)

Solid Content: 62±1.5%

Gel Time: 15-25min

Storage Period: 4 month(below 25℃)

Manufacturing Process: filament winding or spray up process

Feature: high distortion temperature

Application: high-temperature flue and smoke pipe

Delivery Time: 20 days after deposit in account

Purity: 55%

Place Of Origin: Jiangsu, China

| Selling Units | : | kilogram |

| Package Type | : | packed in plastic box , 20kg/drum |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

SWANCOR 907 series products are phenolic Epoxy vinyl ester resins with high crosslinking density and good heat resistance (The heat distortion temperature can reach 150 ℃ or even higher), especially for chlorine-containing solutions or organic solvents. It can be used in some occasions where the temperature is relatively high, such as the preparation of high-temperature flue and smoke pipe, and in the chlor-alkali industry, papermaking Industry, oil and gas storage, electroplating industry, metal smelting industry, etc. are also widely used.

1. Surperior mechanical properties and chemical resistance at elevated temperature.

2. High heat distortion temperature

3. With excellent fatique resistance.

4. Suitable for more aggressive corrossive applications.

5. Lower casting color

| Appearance | light yellow transparent liquid |

| Density | 1.06±0.02kg/L |

| Viscosity | 430±150 cps (LVT#3-60rpm/25℃) |

| Solid content | 62±1.5% |

| Gel time | 15-25min (55%MEKPO:1.2%,6% cobalt Octoate 0.4%,100%DMA:0.05%,temperature:25℃ water bath) |

| Storage period | 4 month(below 25℃) |

Product data sheet

| Item | Data | Test method |

| Tensile strength | 76-90MPa | ASTM D 638 |

| Tensile modulus | 3.4-3.7GPa | ASTM D 638 |

| Elongation | 2.5-4.0% | ASTM D 638 |

| Bending strength | 124-145MPa | ASTM D 790 |

| Bending modulus | 3.7-4.1GPa | ASTM D 638 |

| Distortion temperature | 144-150℃ | ASTM D 638 |

| Hardness | 40-46 Barcol | ASTM D 2583 |

Chemical: 31% HCL , temperature 60℃

Vinyl Resin used : SWANCOR CHEMPULSE 907

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.